The Thermoforming Process Compared with Injection Molding

How to Choose?

Advak Technologies is a premier manufacturer and supplier of thermoformed plastic components, offering pressure thermoforming, vacuum thermoforming and acrylic shaping.

Thermoforming

- Thermoforming heats a two dimensional thermoplastic sheet and uses vacuum and/or pressure to form that sheet into a three dimensional shape.

- It is a single sided process, only one side of the sheet is controlled by the tool. The wall thickness is fully customizable.

- It is typically used for production quantities of 250 to 3000 annually, has a lower tooling cost, fast product development and accepts color and texture.

Plastic Injection

- Plastic injection molding can be used to make plastic parts for effective replication of identical finished products.

- Injection molding has a very high tooling cost, but for large quantities, the cost per part is reduced.

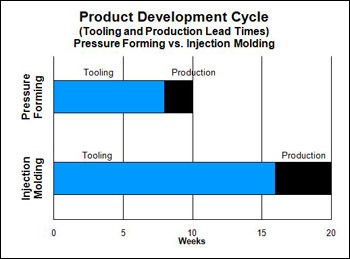

Product Development Cycle

The combination of tooling and production time provides a measure of comparison. For pressure forming, the typical tooling time is 0-8 weeks, and first production typically happens within 2 weeks of that. With injection molding, tooling usually takes 12-16 weeks with up to four more weeks for production.

So, thermoforming clearly is the preferred manufacturing technology when time-to-market is an important consideration.

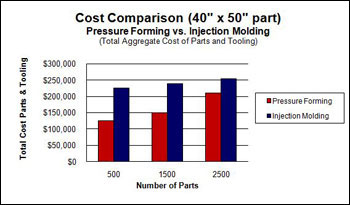

Mold (Tooling) Cost Comparison

The size of the plastic part is also a consideration in the tooling cost. As the size of the part increases, so does the disparity in tooling costs between thermoforming and injection molding. For a 20″ x 30″ part, the injection molding tooling is about twice the cost of thermoforming. With a 50″ x 60″ part, injection molding is more than three times the cost. So as the size of the part increases, the economics of thermoforming are better.

Thermoforming Alternatives

While Advak Technologies exclusively offers thermoforming, there are circumstances where other plastic manufacturing processes such as plastic injection molding are a better choice. These circumstances include high volumes and very complex designs.

Please Contact Us for assistance.

Terminology Note

Advak Technologies and the plastics industry typically use the terms “thermoforming” and “forming” interchangeably. So plastic thermoforming is the same as plastic forming.

Contact Advak Technologies

Please Contact Us for assistance or to get a quote for custom plastic thermoforming contract manufacturing using any of these thermoforming technologies.